By Victor Rivera-Diaz, Staff Researcher and Writer at Save The Water™

Here at Save The Water™, we have developed an advanced water purification solution called the eNox™ System. It can destroy harmful organic molecules. In short, it chemically transforms them into environmentally friendly molecules of water and carbon dioxide.

What Makes the eNox™ System Unique?

The eNox™ System combines hydrogen, ozone, and/or a catalyst with an ultraviolet (UV) light source that can be applied to wastewater streams. This combination creates a powerful chemical reaction that leads to a hydroxyl radical. Simply put, a hydroxyl radical is a highly reactive molecule that is often called the “detergent” of the universe. The hydroxyl radical can destroy problem molecules. Which is to say, “problem molecules” fall under environmental regulations, such as unstable and other organic compounds.

Among its many applications, the eNox™ System is notable for its flexibility. For instance, it can utilize either ozone or hydrogen peroxide as the oxidizing agent. Also, it can harness the strength of solar-powered oxidation through a simple adjustment of the solar collector. Most importantly, it doesn’t transfer the chemicals it destroys to other forms, which must in turn be disposed of. As a result, the eNox™ System eliminates the cost and burden of managing secondary waste.

What Goes Into its Design?

The eNox™ System incorporates an expertly designed reactor. This reactor ensures a maximum mixture of the oxidizer and UV radiation to treat wasterwater. In addition, it minimizes back-mixing of treated water with untreated water.

While UV technology can be electricity intensive, the eNox™ System minimizes the need for UV lamp maintenance. In short, it incorporates a unique design that reduces build-up on the lamp sheaths and other equipment. As a result, it brings energy costs to a minimum.

Moreover, many factors go into the process efficiency of a treatment system:

- type and concentration of contaminants

- temperature

- pH of wastewater

- other factors

To address these many factors, the eNox™ System reduces the concentration of contaminants from levels of parts per million (ppm) to levels of parts per billion (ppb). If necessary, it can even reduce contaminants to undetectable levels.

How to Use the eNox™ System

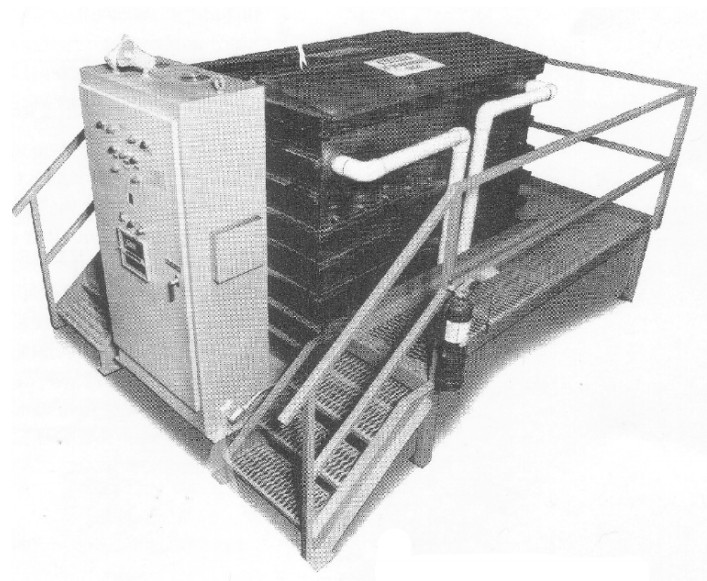

You can easily install and operate the eNox™ system. It ships ready for instant use. And its compact size and lack of secondary waste make it flexible to place.

Once installed, the eNox™ system can be expanded with modules to meet additional requirements. Overall, the simple operation and low maintenance of this system keep its operating costs very low. A 6x8x4’ system can treat 50,000 gallons in a day at about 25 cents per 1,000 gallons. This makes for a very competitive price compared to other facilities.

Finally, the eNox™ System can reduce one of the major maintenance requirements for this type of reactor—ultraviolet lamp replacement. Unlike other systems, which must be powered off when replacing lamps, this system is designed to permit routine changes without the need to be shut down. As a consequence, this has the advantage of water flow going uninterrupted, especially when it’s part of a larger system where water is always flowing. Best of all, the safety design of its chambers and control panel ensure that the entire maintenance procedure can be done without the risk of electric shock or UV eye damage.

Overall Benefits of the eNox™ System

- Simple to operate and low maintenance, thus keeping costs low

- Ready to use out of the box

- No secondary gases or waste

- Maximum mix of oxidizer and UV radiation

- No build-up on lamp sheaths and other equipment

- Shut-down not required during UV lamp replacement

To find out more, check it out here.